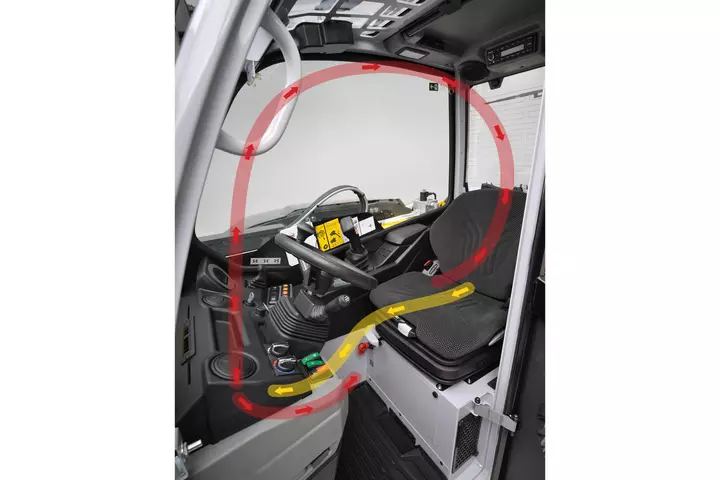

All wheel steering, low centre of gravity and excellent stability distinguish the TH412 telehandler. The integrated driver assistance system VLS (Vertical Lift System) ensures safety, while also increases the operator comfort. The electronically regulated drive system with various operator modes enables an externally productive work operation with the machine. Thanks to its low operating weight and very compact dimensions, the TH412 can be transported on a car trailer without any problems. This makes its flexible for use in many different areas.